Compressed Natural Gas (CNG) fleets have been growing for years, and we would like to provide some insight on our experience as a fleet. CNG is an environmental and economical alternative to gasoline and diesel that companies have incorporated into their trucks and equipment. Lodge Lumber made the switch in 2014 so, let’s look at some of the things we considered in our decision-making process.

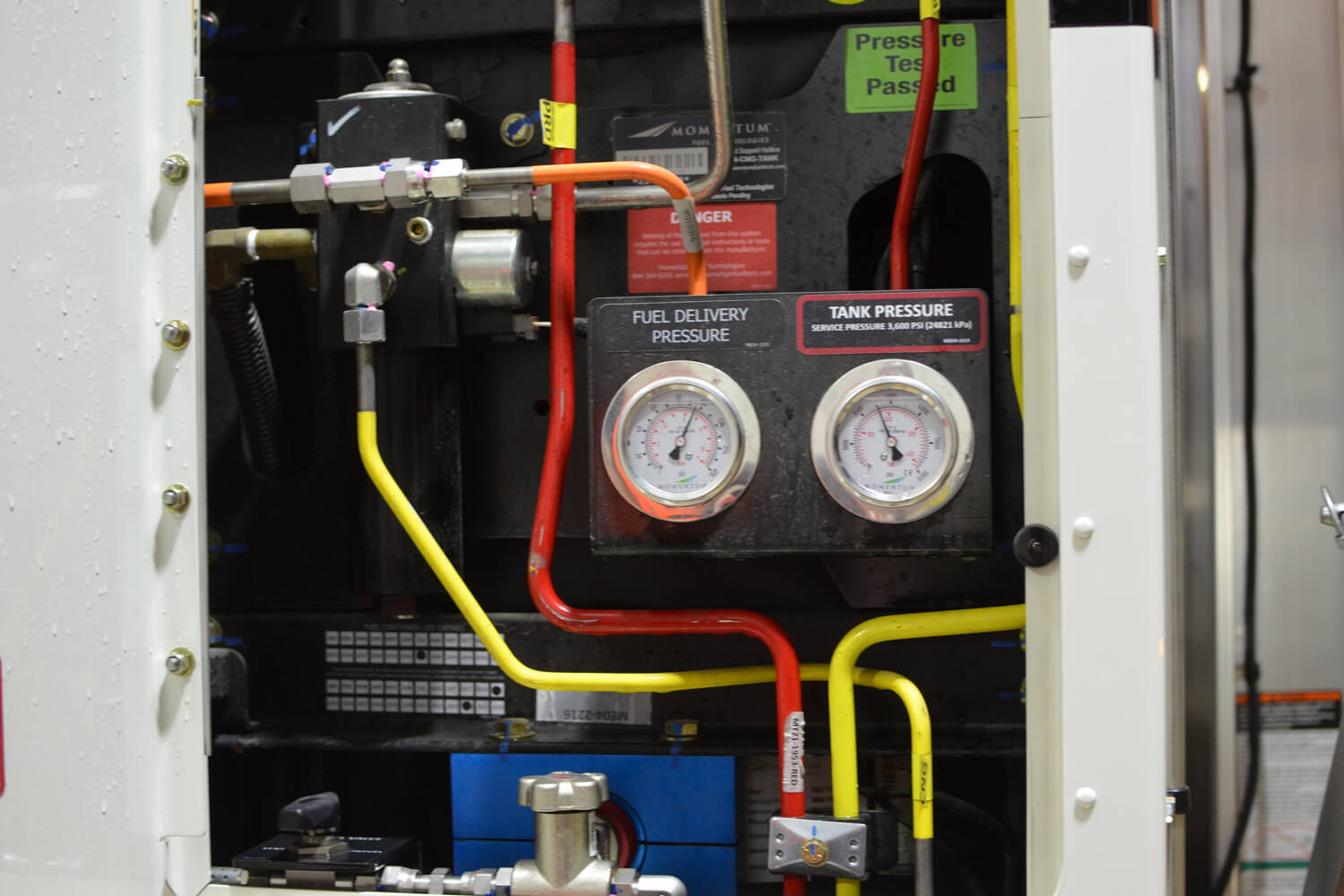

Where does natural gas come from? Compressed natural gas is a gas that can be derived from fossil fuel exploration or as biogas from garbage landfills or wastewater treatment plants. Once the natural gas is produced, it travels via pipeline to a refueling station. At the station, the natural gas is compressed into a fraction of its original volume lessening the resources needed for storage and transportation. When released into an engine, it combusts with oxygen just like gasoline or diesel, creating energy that powers the engine.

Often, CNG is cheaper than traditional liquid fuels. It is also more efficient, making it attractive for companies who want to save money on their fuel costs while reducing their environmental impact. Because CNG is dispensed from pumps instead of underground tanks, there is almost zero environmental risk for leaks.

When companies switch to compressed natural gas for their vehicles, they are making a conscious effort to reduce their carbon footprint. In fact current natural gas trucks operate cleaner or at 90% less Nitrogen Oxides (NOx) than the current diesel standard. The emissions produced by burning CNG are odorless, non-toxic, and non-corrosive compared to those produced by conventional fuels like gasoline or diesel.

CNG vehicle procurement or conversion can be a challenge as CNG vehicles can cost up to 50% more than their diesel or gasoline equivalent. Grants and federal tax credits can help offset these price differences.

CNG also requires special infrastructure for storage and fueling which could be cost prohibitive depending on where you live or operate your business from. Your potential site also must be located near or on an existing natural gas pipeline. Check with the local jurisdiction having authority to determine the rules and regulations for installing a natural gas station. Refueling station options vary from fast fill, time fill, or virtual pipelines. Each type offers various benefits to fleets. Finally, CNG can take longer to fill your tank and you may notice up to a 10% reduction of fuel economy compared to gasoline and diesel equipment. CNG stations can be hard to find in some areas, however, there are a growing number of public and private CNG stations across the country due to its increasing popularity. View the station locator on the AFDC website: Alternative Fuels Data Center: Alternative Fueling Station Locator (energy.gov). Many local and state governments are also providing financial support for building new stations! TCEQ’s funding page: Protect the Lone Star State – Texas Commission on Environmental Quality – www.tceq.texas.gov.

Overall, Compressed Natural Gas (CNG) has many advantages over traditional fuels such as when used for powering vehicles including lower prices per gallon/liter and reduced tailpipe emissions. Additionally, when used properly there can be significant cost savings associated with maintenance since fewer parts need replaced due to less wear-and-tear on the vehicle components caused by burning this type of fuel source. Before making the switch, fleets should consider the following: the cost difference between fuel, maintenance cost savings, reduction in tail pipe emissions, fuel availability along the routes, tank size for maximizing daily operations, the cost of the vehicle, any funding opportunities and tax credits. For infrastructure, rules and regulations, pipeline availability, funding opportunities, and tax credits should be considered. These considerations will help guide fleets to do what is best for the fleet.